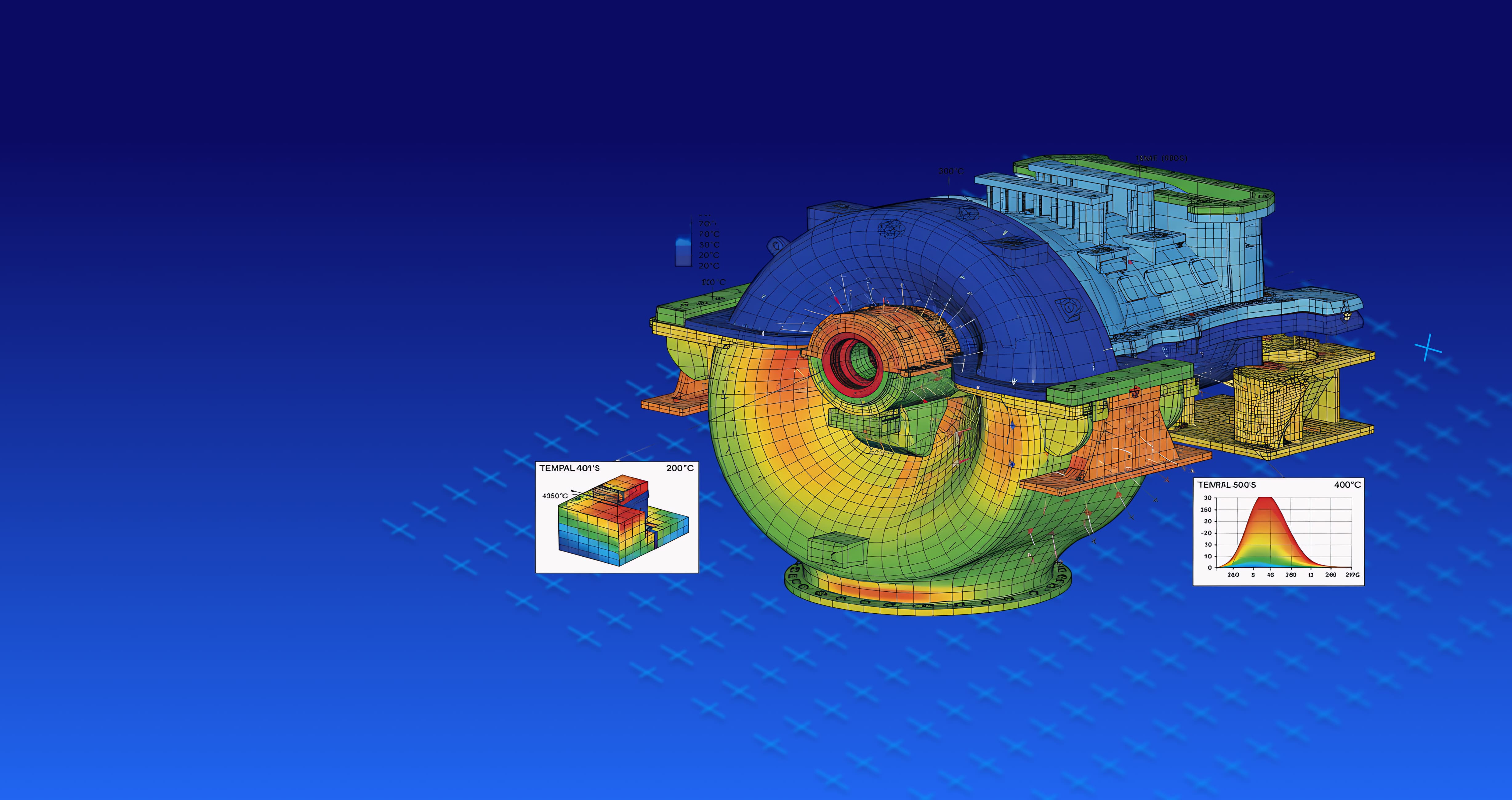

Achieve superior energy performance and product longevity by accurately predicting heat transfer and thermal stress.

CAE is where every great product begins—not with physical tests, but with a fundamental question: Can this be designed better, faster, and smarter? As one of the worlds foremost technical simulation companies, we leverage advanced Computer-Aided Engineering (CAE) to answer that question before any material is sourced. By utilizing the power of simulation, we eliminate the reliance on expensive, slow physical testing and development. This insight-first philosophy translates directly into tangible benefits for our clients: reduced costs, shorter lead times, and demonstrably superior results compared to traditional engineering practices. .

Dynamic simulation is essential for testing vehicle crashworthiness and aviation safety—scenarios that are impractical to test repeatedly in the physical world. For cars, our analysis accurately models everything from passenger dummies and restraints to fuel systems and airbags, achieving near-perfect real-world validation. In aerospace, this ensures the structural resilience of aircraft under various flight conditions, including the extreme stress of an emergency landing.

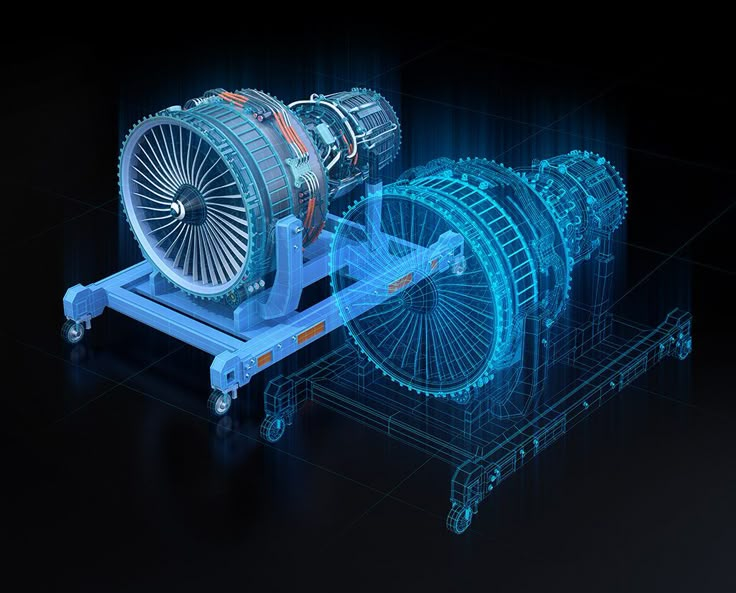

Dynamic simulation is how we model your product's performance against real-world chaos, like high-speed impacts or intense, time-varying forces. We generate precise digital replays of these events, offering engineers immediate, deep insight into system behavior. This capability is used to test and refine critical components—like engines and drivetrains—before any physical materials are committed. By catching flaws early, we slash prototype costs and rapidly confirm your product's reliability and safety across diverse industries.

Computational Fluid Dynamics (CFD) is the digital science of understanding how gases and liquids move around your designs. By merging fluid science with thermodynamics, CFD generates detailed insights into complex airflow, thermal management, and fluid momentum.